- About

- News

-

Business

-

Engineering Construction

Committed to excellence in engineering construction and project execution. -

Mining And New Materials

Integrating mining operations with the development of cutting-edge new materials. -

Clean Energy

Committed to the development of clean energy solutions for a sustainable future.

-

-

Technological

-

Major Awards

Honored with major awards that reflect our excellence and leadership in the industry. -

Research And Development Platform

Equipped with a state-of-the-art research and development platform to support cutting-edge solutions. -

Science And Technology Achievements

Showcasing our breakthroughs and applied technological accomplishments in infrastructure development. -

Innovation Dynamics

Stay updated on our latest innovations and technological advancements.

-

- Brand

- Human Resources

-

Social Responsibility

-

Rescue And Disaster Relief

Committed to emergency rescue and disaster relief with swift and effective response capabilities. -

Poverty Alleviation/Rural Revitalization

Committed to poverty alleviation and rural revitalization for sustainable community development. -

Social Welfare(Donate To Support Education)

Committed to social welfare through philanthropic efforts, including educational funding and support. -

Sustainable Report

Our Sustainability Report details our commitment to environmental stewardship, social responsibility, and sustainable growth.

-

-

Investors Relation

-

Stock Price Situation

Overview of our stock performance and market trends. -

Temporary Notice

Timely announcements and urgent notices to keep stakeholders informed. -

Regular Report

Regular reports providing insights into our financial performance and business operations. -

Dividend Distribution Situation

Information on dividend distribution and shareholder returns. -

Investor Hotline

Dedicated investor hotline providing timely support and information.

-

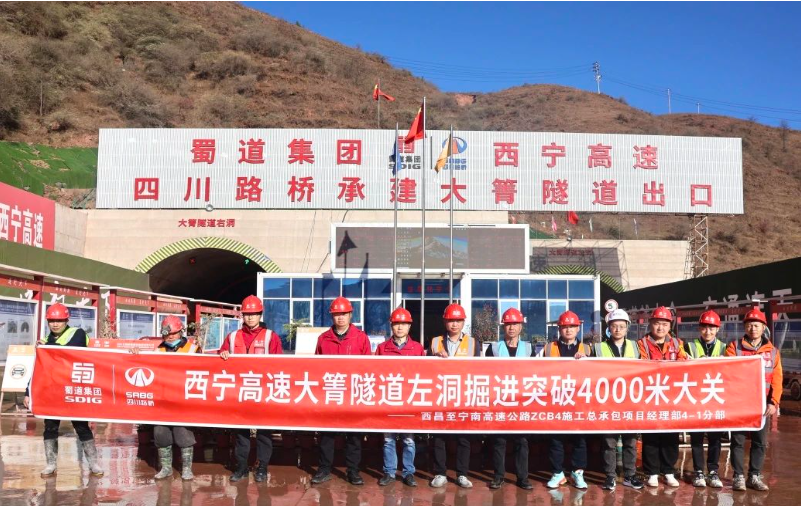

Sprint for the first quarter and strive for a good start | 4000 meters! There has been new progress in the Daqing Tunnel of Xining Expressway

Pubdate :2025-05-22

On March 3rd, the left tunnel excavation of the Daqing Tunnel of the ZCB4-1 section of Xining Expressway, constructed by Shengtong Company, officially broke through the 4,000-meter mark, marking the entry of tunnel construction into the final sprint stage.

As one of the key control projects of the Xining Expressway, the Daqing Tunnel is over 10 kilometers long, with a maximum burial depth of 720 meters. The longitudinal slopes of both the left and right lines are 2.5%, and the height difference between the entrance and exit is 250.35 meters. It is currently the world's longest longitudinal slope expressway super-long tunnel with the highest height difference between the entrance and exit. The tunnel body as a whole passes through a zone with a seismic intensity of nine degrees, running parallel and crisscrossing along the Autonomous Mo-Qiaowo Fault and the Zemuhe New Century Fault Zone. The geological conditions are complex and the water intake is large, making the construction extremely difficult and posing significant challenges to the project's safety production, environmental protection and other management aspects.

During the tunnel excavation process, the project vigorously promoted the automated section monitoring system. By applying technologies such as AI and deep learning convolutional neural networks, it conducted reference perception, precise analysis and early warning of the micro-deformation process of the tunnel. The extensive application of intelligent safety helmets has achieved a five-in-one integration of "perception, analysis, service, command and monitoring", creating a new model for engineering safety monitoring. At the same time, it has pushed the intelligence level of the Daqing Tunnel to a new height.

In view of the actual situation of large water inflow in the tunnel, an integrated and collaborative management system of clean and sewage separation, sewage treatment, and water quality monitoring and early warning has been established to achieve functions such as integrated drainage of the left and right tunnels, clean and sewage separation, automatic water quality monitoring, and early warning of over-limit water quality. The tunnel sewage is purified and discharged to the first-level standard, contributing to the construction of a green Xining expressway.

Next, the project department will continue to uphold the concept of "safety first, quality supreme, and green environmental protection", constantly innovate technologies, optimize management, ensure the smooth breakthrough of the Daqing Tunnel, and contribute to the early opening of the Xining Expressway.